The company «Farconi» has two production facilities located near the Georgian city of Kutaisi, Imereti Region in ecologically clean place. The total production area is more 4000 square meters.

Production facility No. 1

Production facility No. 1 is intended for bay leaves processing which is certified by BIO standards. Bay leaves are grown on company’s own plantation located in a remarkably beautiful place.

Production facility No. 2

Production facility No. 2 is designed for processing medicinal herbs, dried wild berries and spices.

STAGES OF TECHNOLOGY

PROCEDURE

Technology procedure of «Farconi» for processing medicinal herbs, dried wild berries and spices consists of the following stages:

Harvesting and delivery

Harvesting and delivery of raw materials to the warehouse. Raw materials are delivered from all over Georgia. Raw materials harvesting is made by hand, controlled and regulated by the company quality control department.

Pre-sorting of raw materials

Pre-sorting of raw materials. It is performed in 2 ways: by hand and with special equipment. At this stage, raw materials which do not comply with the requirements of standards and specifications are removed.

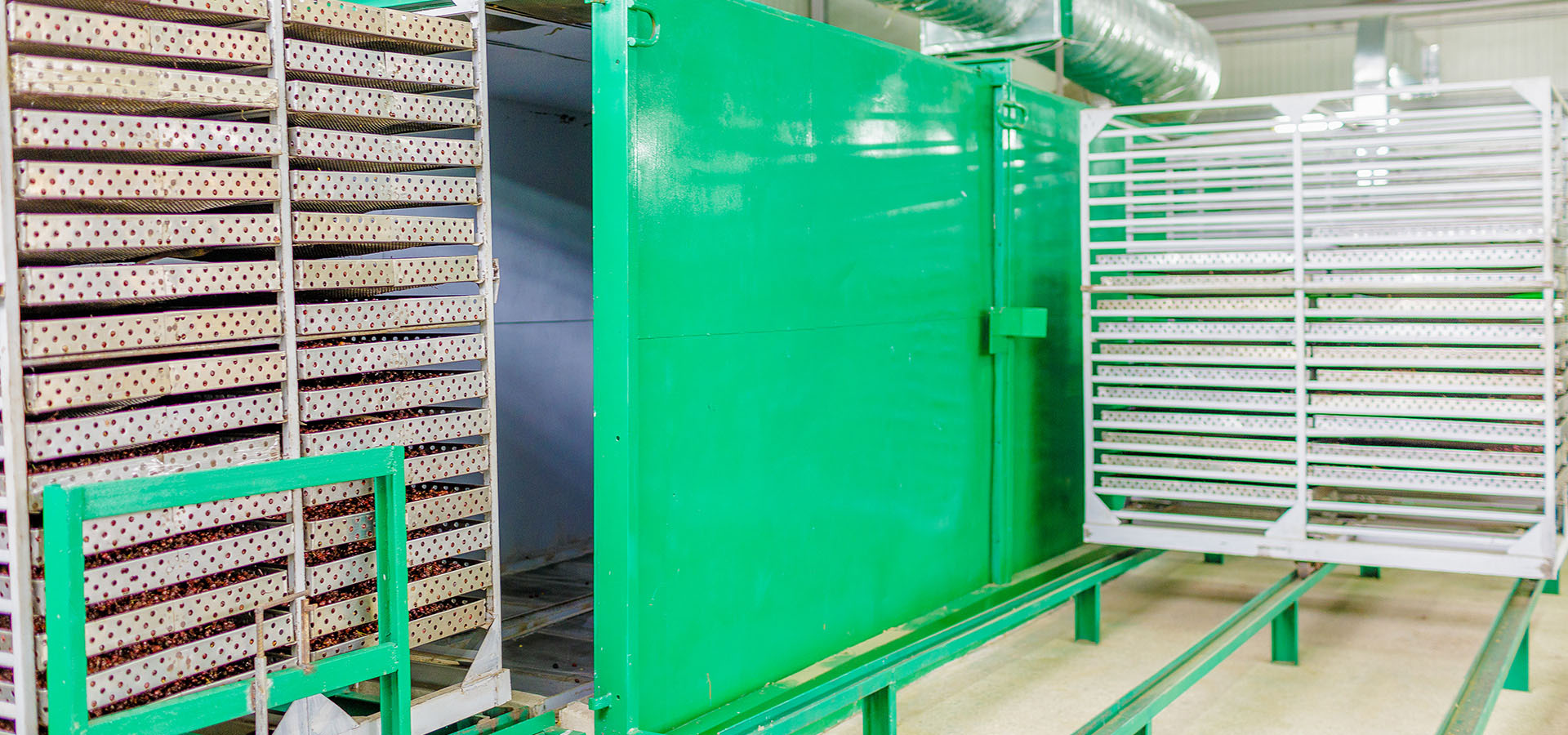

Drying of raw materials

Drying of raw materials (completing of drying is possible at different stages of the process). During the drying process, removal of moisture occurs as a result of hot air passing through the layer of raw materials.

Crushing and cleaning of raw materials

Crushing and cleaning of raw materials. At this stage raw materials are crushed into different fractions in accordance with customer requirements, on the separate line furthermore is carried out spices grinding. During the cleaning process operation light, big, small, long, short and hard-to-separate weed impurities are removed from the raw materials.

Raw materials blending

Blending of raw materials. Raw material components are mixed using special equipment in accordance with the process requirements and proportions to achieve product homogeneity.

Packing of finished products

Packing of finished products. The finished product is further delivered to pre-packing and packing. Products are packed in compliance with customer requirements.

THE COMPANY AVAILS

OF DIFFERENT WAREHOUSES:

Warehouse for storage of raw materials prior to processing.

Warehouse for storage of raw materials after processing.

Warehouse for storing products with a high content of aromatic substances.

Special warehouse for storing BIO products.

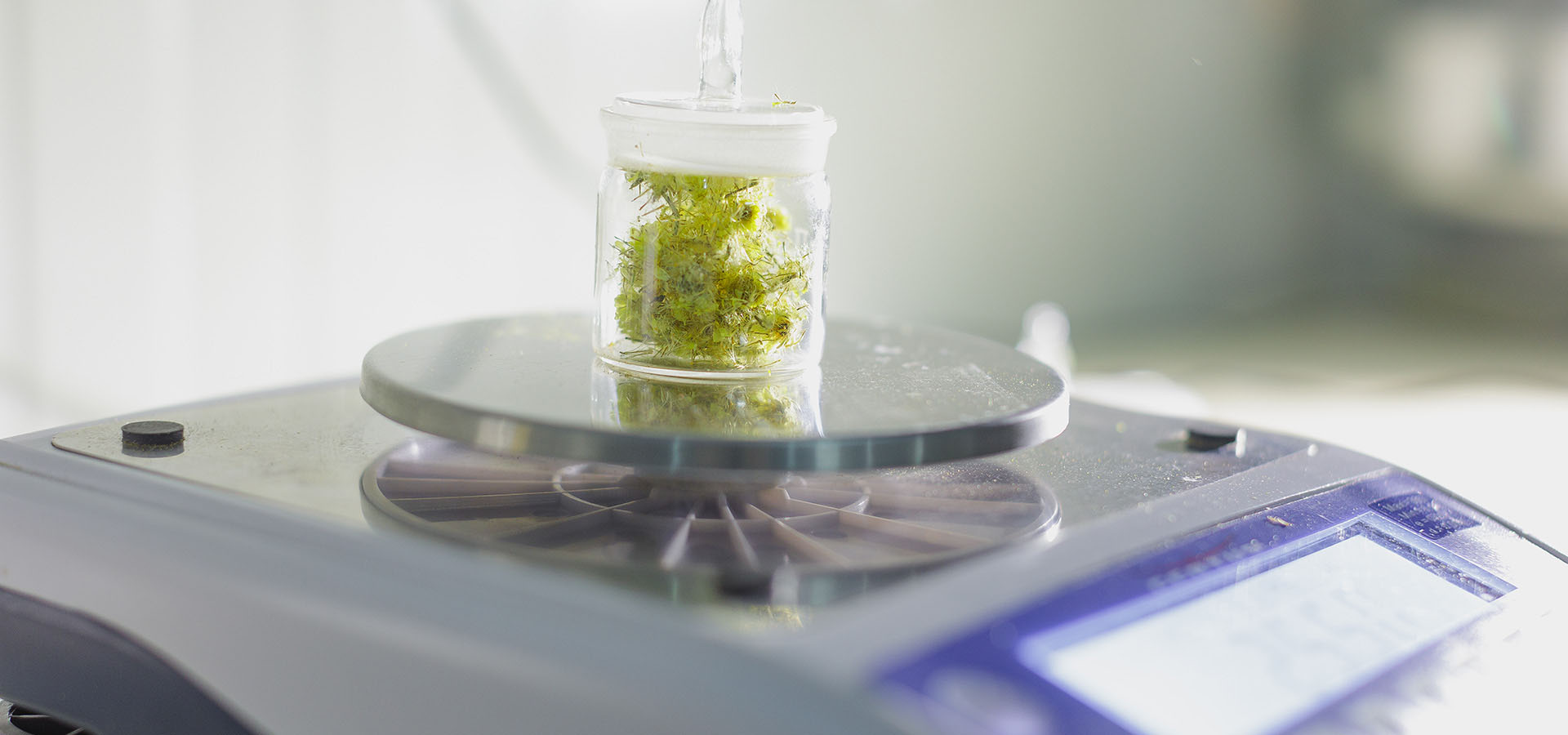

QUALITY CONTROL

At all stages of production quality control is carried out by the laboratory and quality control department.

The laboratory carries out the following types of tests:

– Organoleptic test (appearance, color, smell, taste).

– Physicochemical analysis: moisture, ash, impurities, etc.